Demand for textile fibres is growing globally and sustainability expectations are increasing both in the minds of consumers and regulators. Forward-looking companies are focused on capturing the market of tomorrow and investing in new, more sustainable fibre production technologies.

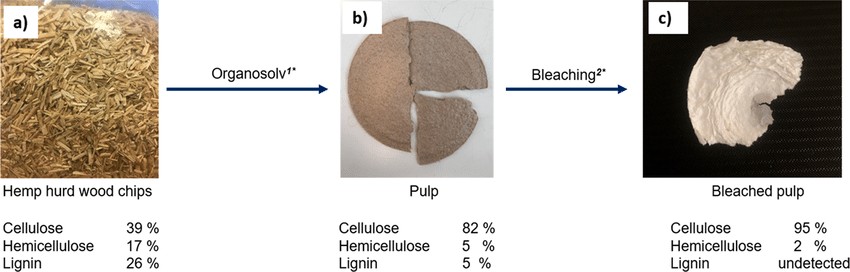

Spinnova has developed breakthrough patented technology for making textile fibre out of wood pulp or waste, such as leather, textile or agricultural cropping waste, without harmful chemicals or dissolving. With Spinnova technology, the pulp raw material is mechanically refined and transformed into spinning-ready fibre suspension without harmful chemistry — no dissolving, no regeneration. Spinnova technology is the only process in the world that converts cellulose into textile fibre in this way. Upon spinning into filament, the suspension flows through a unique nozzle at a high pressure. The right extrusion causes the fibrils to rotate and align with the flow to create a natural textile fibre. The fibre is then simply dried, collected and post-processed, ready for spinning into yarn.

SPINNOVA® fibres are blended with other preferred fibres and can be integrated into innovative and conventional textile processing methods, similar to the processing of cotton. The fibre properties, such as anti-odour properties and look and feel, are comparable to those of other natural cellulosic fibres, such as cotton. Spinnova fibre can be used in textiles as well as in various insulation and composite applications. Position as a front-runner with a clean and modern data-driven production process without any chemical dissolving steps. Differentiate from the competition with a disruptive resource-efficient fibre with a natural feel and customisable properties. Use a variety of raw materials – the same process can be used for anything from wood pulp and straw pulp to recycled textile pulp.

SPINNOVA® fibre production technology is based on years of development and industrial experience. Our reference plant in Jyväskylä, Finland, is operated by our joint venture company, Woodspin and has a nameplate capacity of 1000 tons of SPINNOVA® fibre per year. The plant has been used extensively to validate new technology concepts, which Spinnova will implement in next-generation customer projects to increase capex and opex efficiencies. SPINNOVA® is a novel fibre which is blended with other preferred fibres to make yarn and fabrics. The fibre can be integrated into innovative and conventional textile processing methods, such as those used in cotton processing.

The fibre properties, look, and feel are comparable to those of natural cellulosic fibres, such as cotton, while reducing odour intensity compared to cotton. SPINNOVA® fibre can be produced from wood pulp or waste, such as leather, textile, or agricultural cropping waste, without harmful dissolving chemicals. SPINNOVA® fibre is a biobased textile fibre made from renewable raw materials. Its production creates no side streams and has minimal CO₂ emissions and water use. SPINNOVA® fibres are biodegradable and recyclable: they can be recycled in the same process without losing quality. In addition, SPINNOVA® fibres have been successfully recycled in the CIRCULOSE® process on a test scale. Spinnova is committed to using only sustainable raw materials, such as FSC-certified wood and waste.