Power Consumption of Ring Spinning Frame Using Plastic T-in Cylinder

Abstract

Khen Maung, Director (Operations), NZ Textiles Ltd, Narayangonj, Bangladesh.

Mohammad Ali, Professor, Department of Industrial and Production Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh.

Ashraful Islam Ansary, Senior Assistant General Manager, Thermax Milange Spinning Mills Ltd, Narsingdi, Bangladesh.

*Corresponding Author: dr.ali@ipe.butex.edu.bd

Received: October 20, 2024, Accepted: November 1, 2024, Published: November 7, 2024

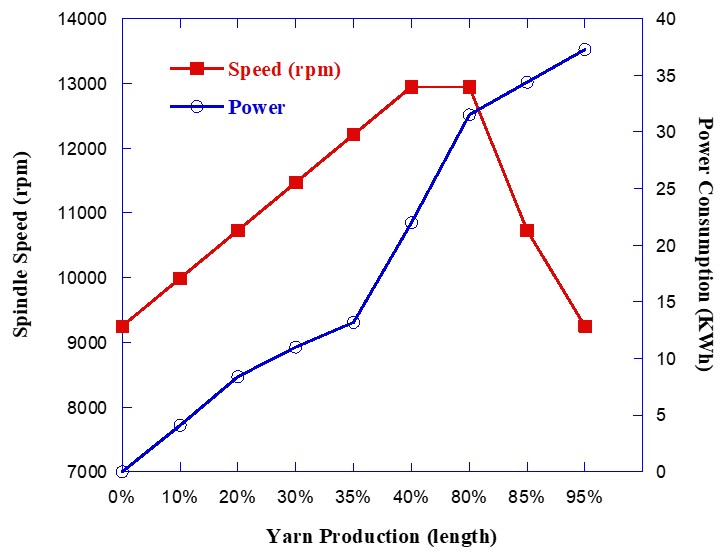

Spinning factory consumes the highest amount of electrical power compared to weaving, knitting, dyeing, and garment factories of the textile industry. A typical spinning unit of 20000 spindles requires about 2 megawatts (MW) of connected power to run the process machinery. Power is also a major cost component of yarn production after raw materials, and thereby the reduction of power cost is a paramount concern of the management of the spinning unit. This investigation aims to reduce power consumption of the ring frame using a plastic T-in cylinder. 2850 meters of 30 Ne yarn fineness was spun in a ring frame with a plastic T-in cylinder, and the same length of that yarn fineness was produced by the ring frame with a metallic T-in cylinder from the same feed material (roving). Power consumption was measured by a digital power meter during the production of the yarn at different set lengths. The power consumption was 39.5 kWh and 37.3 kWh, corresponding to metallic and plastic T-in cylinders. The reduced power consumption suggests that the setting up of a new spinning factory can be considered to be designed by ring frames with plastic T-in cylinders.

Georgia Reader Reply

Et rerum totam nisi. Molestiae vel quam dolorum vel voluptatem et et. Est ad aut sapiente quis molestiae est qui cum soluta. Vero aut rerum vel. Rerum quos laboriosam placeat ex qui. Sint qui facilis et.