Power Consumption of Ring Spinning Frame Using Plastic T-in Cylinder

Abstract

Khen Maung, Director (Operations), NZ Textiles Ltd, Narayangonj, Bangladesh.

Mohammad Ali, Professor, Department of Industrial and Production Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh.

Ashraful Islam Ansary, Senior Assistant General Manager, Thermax Milange Spinning Mills Ltd, Narsingdi, Bangladesh.

*Corresponding Author: dr.ali@ipe.butex.edu.bd

Received: October 20, 2024, Accepted: November 1, 2024, Published: November 7, 2024

Spinning factory consumes the highest amount of electrical power compared to weaving, knitting, dyeing, and garment factories of the textile industry. A typical spinning unit of 20000 spindles requires about 2 megawatts (MW) of connected power to run the process machinery. Power is also a major cost component of yarn production after raw materials, and thereby the reduction of power cost is a paramount concern of the management of the spinning unit. This investigation aims to reduce power consumption of the ring frame using a plastic T-in cylinder. 2850 meters of 30 Ne yarn fineness was spun in a ring frame with a plastic T-in cylinder, and the same length of that yarn fineness was produced by the ring frame with a metallic T-in cylinder from the same feed material (roving). Power consumption was measured by a digital power meter during the production of the yarn at different set lengths. The power consumption was 39.5 kWh and 37.3 kWh, corresponding to metallic and plastic T-in cylinders. The reduced power consumption suggests that the setting up of a new spinning factory can be considered to be designed by ring frames with plastic T-in cylinders.

Full Text

1. Introduction

Textile and readymade garment (RMG) industry is one of the largest manufacturing industries that supplies clothing and other related products for human beings [1]. This industrial sector is also the economic backbone of many developing countries [2]. The developing countries face many problems related to the supply of fuel to the textile and RMG industry. The textile and RMG industry generally use natural gas to convert it into electrical power by gas generator [3]. The availability and cost of the supply gas is also a factor for the efficient running of the textile and RMG industry. The fuel cost of other sources is also higher than the natural gas [4]. Natural gas is a non-renewable energy source and is extracted by drilling into the earth [5]. In order to reduce the use of natural gas and power consumption by the textile industry and especially ring spinning, it has to put attention on it. Spinning is such a kind of production unit that requires a substantial amount of power to run the process machinery. For instance, 2 megawatts of power are required to run the process machinery of a ring spinning unit having 20000-spindle capacity. Fig. 1 shows the power requirement for various process machinery of a ring spinning factory [6-7].

Fig. 1. Distribution of power requirement for various processes of a ring spinning factory.

It is evident that the ring section of a ring spinning factory consumes around half of the installed power among all processes. Spindles of the ring frame run at 15000-20000 rotations per minute (rpm) for inserting twist in yarns. Many efforts have been paid in the recent decade in order to reduce the power consumption of the ring frame. An electrical inverter has been used in a ring frame to control electrical frequency for adjusting the rotational speeds of the spindles required as per the specific diameter of the yarn carriers (cops or bobbins to store or wind yarns on them) [8]. Ring frame manufacturers like Rieter, Marzoli, Toyoda, Lakshmi, Jingwei, and others have developed ring frames with multiple motors and a large number of spindles [9]. World-leading spindle manufacturers such as Novibra and Texparts have introduced spindles with less wharve diameter for achieving increased rotational speeds of spindles with the same energy consumption, or the spindles can run with the same rotational speeds utilizing less electrical power [10]. Power monitoring systems have also been developed by the manufacturers, like Pinter-Caipo, Premier, Datalog, and Mag Solvics, for real-time monitoring of the power consumption of ring frames so that the management can understand how well the ring frame is being maintained and whether the ring frame is consuming higher energy than usual due to the faults of the motor, bearings, and other power transmission systems, and accordingly, the mill management can take preventive measures to avoid unnecessary loss of electrical power [11]. Ring frames are designed with T-in cylinders that drives the spindles. Fig. 2 shows the driving structure from the motor to the spindles of a ring frame.

Fig. 2. Driving structure from the motor to a spindle of a ring frame. The motor drives the shaft containing the T-in cylinder, and the T-in cylinder finally rotates the spindle.

The motor has a pulley that uses electrical power to drive a T-in cylinder. The mass of the T-in cylinder determines the power required for the driving motor. It can be noted that as of today all commercial ring frames are normally supplied with a metallic T-in cylinder. It was necessary to equip a metallic T-in cylinder due to the strength of the materials and lack of availability of other materials of similar strength. The plastic industry and polymer-based composites have gained much attention for the use of alternative materials to metals [12]. Very recently, ring frame manufacturers can supply their machine with plastic T-in cylinders considering the global crisis of energy as well as sustainable environment [13]. Many researchers tried to reduce energy consumption of ring frames with respect to the installation of a new type of bearing [14], speed change [15], package diameter [16], and implementation of a timing belt [17]. All efforts were successful in reducing power consumption, but spinning factories are still struggling in reducing power consumption of ring frames to a greater extent [18-19].

This study has investigated the opportunity of using a plastic T-in cylinder in a ring frame. The objective of this study is to find out the amount of energy consumption of a ring frame equipped with a plastic T-in cylinder compared to a metallic one.

2. Methodology

2.1 Raw materials

Dope-dyed viscose and cotton fibers were used at a ratio of 90:10, respectively.

2.2 Process machinery

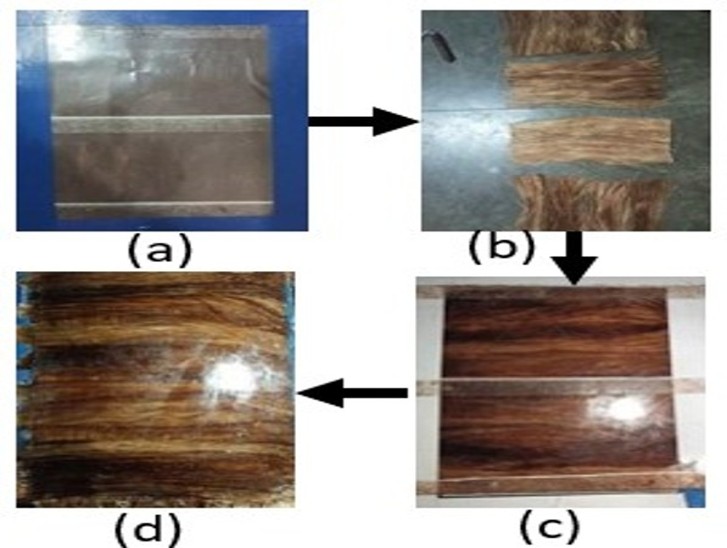

Rieter automatic mixing and blending and carding machines were used for opening and individualization of fibers. Mixed fibers were passed through the Rieter drawing for the production of sliver. Finally, the sliver was used to produce roving by the China simplex machine. A ring frame with 516 spindles of the Jingwei brand and another ring frame with the same number of spindles and brand were used to produce yarns of 30 Ne fineness. A metallic T-in cylinder was used in one ring frame, and a plastic T-in cylinder was used in another ring frame, as shown in Fig. 3.

Fig. 3. Metallic T-in cylinder (a), plastic T-in cylinder (b), plastic T-in cylinder mounted in a ring frame (c), and metallic T-in cylinder mounted in a ring frame (d).

Yarn length was fixed at 2850 meters for both ring frames. Similar spindle speeds (corresponding to yarn length (%) to be wound on cops were programmed in the inverter for the production of yarns.

2.3 Measurement of power consumption

A digital power meter was used to take the readings of power consumption. Several readings were taken from the power meter with respect to yarn production length during the winding of three and a half hours for both cases of plastic and metallic T-in-cylinder. Three phases of the electrical line were connected to the ring frames.

3. Results and Discussions

3.1 Effect of spindle speed pattern on power consumption

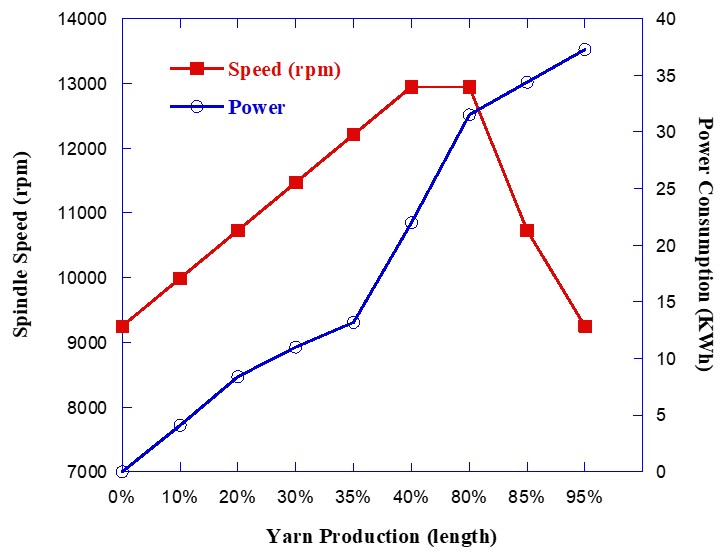

Yarn package diameter (cops) affects the speed of the spindles. At the initial point of winding, the diameter of the cops is less, and the angle of winding of yarn to the cops is less, which produces excessive winding tension on the yarns, causing higher yarn breakage. In order to avoid yarn breaks, spindle speed is kept as low as possible at the beginning of winding. Fig. 4 shows the spindle speed profile with respect to yarn length from the initial point of winding (0%) to the set length of yarn.

Fig. 4. Power consumption against the pattern of spindle speed.

A linear relationship was found between the spindle speed and power consumption up to the point where the spindle speed reaches its maximum. A gradual increase in spindle speed was possible due to an increase in the winding angle of yarn to the cops. When the diameter of the cops starts to become large, then again winding tension increases because of the excessive diameter of the cops. At this stage, spindle speed was to be reduced to minimize the yarn breakage rate. The power line of the figure shows the gradual accumulation of power from beginning to end, which is almost linear.

3.2 Effect of metallic and plastic T-in cylinder on power consumption

Fig. 5 depicts the power consumption of metallic and plastic T-in cylinder as a function of yarn production of set length as a percentage.

Fig. 5. Power consumption of metallic and plastic T-in cylinder with respect to yarn production length.

Metallic and plastic T-in cylinder both show linear progression of power consumption as explained by Fig. 4. The power consumption of the plastic T-in cylinder was less than that of the metallic T-in cylinder at most of the points of winding of yarn to cops. Power consumption for the metallic T-in cylinder and plastic T-in cylinder was 39.5 kWh and 37.3 kWh, respectively, during the yarn production of 3.5 hours. The amount of power savings was 2.2 kWh (39.5-37.3). This is due to the weight difference between the metallic and plastic T-in cylinder. The weight of the metallic cylinder was 1120 grams, and the plastic T-in cylinder was 540 grams. As the weight of the metallic T-in cylinder was higher, the power requirement to drive it by the motor was also higher, and similarly, the power consumption was less in the case of the lightweight plastic T-in cylinder. In order to find the effect of the brand of ring frame, Marzoli and Jingwei ring frames were used to compare. Fig. 6 shows the effect of power consumption on the type of brand of ring frame.

Fig. 6. Power consumption of Jingwei and Marzoli brand ring frame using metallic T-in cylinder for the production of yarn length of 1850 meters.

The Jingwei brand ring frame results in less power consumption as compared to the Marzoli brand ring frame. This result also suggests that the structure of the ring frame with respect to bearings, motor, lubricant applied to the machine, maintenance of the machine, and other factors can influence the results.

3.3 Effect of yarn production length (doff) on power consumption

Doff length is the length of yarn to be produced and wound from empty to full cops. Normally spinning factory wants to set a higher doff length in order to reduce the frequency of ring frame stoppage. A ring frame of Jingwei brand was used to produce yarns of two different doff lengths of 3000 and 2000 meters, as shown in Fig. 7.

Fig. 7. Variation in power consumption of Jingwei brand ring frame with two different doff lengths.

3000 meters of doff length shows higher power consumption than that of 2000 meters. As 3000 meters doff length requires more running time of the ring frame and consumes more power than 2000 meters doff length. Though power cost can be saved by a lower length of doffs, the cost of production loss is higher than the power saving, and hence a higher doff length is always desirable.

4. Conclusions

Price hikes and shortages of gas supply initiate spinning factories to save power costs as well as yarn production costs. This study successfully compared the power consumption between the metallic and plastic T-in cylinder of the ring frame and revealed that the plastic T-in cylinder consumes less power than the metallic one. The amount of power savings was 2.2 kWh. Modification of existing Ring frames equipped with metallic T-in cylinders by the plastic T-in cylinder will not bring that many benefits, but if a new spinning factory is built, ring frames with plastic T-in cylinders would be prospective for the reduction of power consumption of ring spinning factory.

REFERENCES

[1] Waleed Hassan Akhtar, Chihiro Watanabe, Yuji Tou and Pekka Neittaanmäki, “A New Perspective on the Textile and Apparel Industry in the Digital Transformation Era”, Textiles 2, 633–656, 2022.

[2] Kaniz Fatema, M. Moniruzzaman, G. Rabbani Mondal,M. Amzad Hossain, “The Relationship between Growth and Quota Restrictions Concerning the Textile and Clothing Industry: A Study on RMG Sector of Bangladesh”, Journal of Economics, Finance and Management Studies, Vol 07 (08), 4834-4847, 2024.

[3] Fibre2Fashion, “Gas Crisis Affects Textile Production in Bangladesh,” 2023.

[4] M. Atiqul Islam, “Energy Auditing and Efficiency of a Ready-Made Garment Factory in Bangladesh: A Case Study” M. Engg Thesis, Brac University, 2021.

[5] Palash Panja, David A. Wood, “cProduction decline curve analysis and reserves forecasting for conventional and unconventional gas reservoirs”, Sustainable Natural Gas Reservoir and Production Engineering, 183-215, 2022.

[6] Madhuri Nigam, Prasad Mandade, Bhawana Chanana, Sabina Sethi, “Energy consumption and Carbon footprint of Cotton Yarn Production in textile industry”, International Archive of Applied Sciences and Technology Vol 7(1), 6-12, 2016.

[7] Y. Dhayaneswaran and L. Ashokkumar, “A Study on Energy Conservation in Textile Industry,” J. Inst. Eng. Ser. B, vol. 94 (1), 53–60, 2013.

[8] El-Sayed M.A.M, “Optimizing Ring Spinning Variables and a Proposed Procedure to determine the Egyptian cotton spinning potential” Journal of Textile and Apparel Technology and Management, Vol 6 (1) 2009.

[9] H.R Sheikh, “Impact of long ring spinning frames on yarn cost”, Pakistan Textile Journal, 2007.

[10] High Speed Spindles, Novibra Product Brochure.

[11] M.K. Prabhakar & Mohan Raj, Pinter–Rolls out 2 millionth Made-in-India spindle monitoring system, The Textile Magazine, 2018.

[12] Tri-Dung Ngo, “Introduction to Composite Materials” IntechOpen, 2020.

[13] Ashvani Goyal, Rajkishore Nayak, Sustainability in yarn manufacturing, Sustainable Technologies for Fashion and Textiles (2), 33-55, 2020.

[14] S Sundaresan, M. Dhinakaran, Arunraj Arumugam “Impact of Bearing Vibration on yarn quality in Ring Frame” Journal of Polymer and Textile Engineering, Vol. 2 (3), 550-59, 2015.

[15] Fahim Bin Alam, Touhidul Islam, Monir Hossan, Mizanur Rahman, “Assessing the Impact of Speed Change on Energy Consumption and Productivity: Investigating Ring Frame Process Parameters, Textile and Leather Review, Vol.5, 509-5024, 2022.

[16] Zheng Tang, Xungai Wang, B. Fraser, “Minimizing Energy Consumption of Yarn Winding in Ring Spinning”, Textile Research Journal, Vol. 74(12), 2004.

[17] Din, Nurunnabi, Fairooz, Rony, Shah, “A cost-effective approach after implementation of timing belt drive in the cotton ring-spinning frame”, Cleaner Engineering and Technology, Vol. 9(7),1-6, 2022.

[18] Erdem Koc, Emel Kaplan, “An investigation on energy consumption in yarn production with special reference to ring spinning, Fibres and Textiles in Eastern Europe, Vol 15(4), 18-24, 2007.

[19] Power consumption in Spinning Mills, Textile School, 2018.

Georgia Reader Reply

Et rerum totam nisi. Molestiae vel quam dolorum vel voluptatem et et. Est ad aut sapiente quis molestiae est qui cum soluta. Vero aut rerum vel. Rerum quos laboriosam placeat ex qui. Sint qui facilis et.