Effect of Acid Wash on Appearance and Physical Properties of Terry and Interlock Knitted Dyed Garment

Abstract

Kaniz

Farhana, Md. Al-Mamun, Md. Sabbir Hosen, Abhisheke Chakrabortty, Hasibul

Hasan, Department of

Apparel Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh, Abu Shadate Faisal Mahamude, College of

Engineering, University Malaysia Pahang, 26300 Gambang, Pahang, Malaysia Corresponding

Author: kanizfar7@gmail.com

The closing step in finishing the garment manufacturing process involves washing, in particular for fashionable garments. Acid washing is a method used in garment finishing to make a valuable aesthetic for a garment. This study examines how two knitted garments—a terry (100% cotton) and an interlock (100% cotton)—are affected aesthetically and physically by acid washing using potassium permanganate and granular thermocol balls as an abrasive. Physical characteristics of the garments were examined after acid washing, and it was found that the garment weight in grams per square meter and spirality increased while their bursting strength reduced. Furthermore, colorfastness to wash, dry, wet rubbing, and pilling was unchanged. This work indicates that acid washing with thermocol balls is effective for making a faded look on terry and interlock garments for their value addition to customers.

Full Text

1. INTRODUCTION

The use of garments is fundamentally social aspects of human beings but also to provide human beings with different environmental protections [1]. Social aspects have gradually become fashionable for garments, especially for the young generation all over the world [2]. Textile and garment manufacturers have developed fashionable denim or jeans garments using various dry and wet treatments [3]. Stone washing is the oldest method to create a fade effect on a denim or jeans garment. Pumice stones are used for denim washing to create a faded, worn-out look to the garment. Pumice stones are placed with the denim garments in a large washing machine. Pumice stones abrade the surface of the denim garment and make wear and tear to create faded effects on garments [4]. Sand blasting is also a conventional process to create faded areas and localized worn effects on denim or jeans garments [5]. Potassium permanganate spray is applied to jeans to create a moderate bleaching effect on the surface of the garment [6]. Decolorization of indigo color is achieved by bleach washing [7]. Laser is the best alternative to potassium permanganate spray and can create a wide variety of surface effects on denim or jeans garments [8]. In order to create a fashion look on knit garments like T-shirts and polo shirts, various technological systems have been developed. Slub yarns, multi-count and multi-twisted yarns, neppy yarns, SIRO yarns, Mozaic yarns, cloudy yarns, and inject yarns are being commercially available during the production of yarns to create different aesthetics in the knit garment. After the production of knit garments, they are also washed by enzymes, softeners, silicone, pigment, and caustic to get desirable fashion and comfort [9-12]. Apart from those techniques, acid washing of knit garments is a popular method for color fading. In the past, denim clothing dyed with indigo dyes was typically acid-washed. The acid wash technique produces a striking color contrast on the clothing [13]. Potassium permanganate (KMnO₄) was used in spray on jeans to create a washing effect on the garment. Potassium permanganate is also used in denim washing. A study demonstrated that the effect of change in concentration of KMnO₄ on physical and mechanical properties of denim jeans during acid washing [14-16]. Thermocol is a small granular or ball-like substance that is being used in garment washing in order to get a similar or better effect produced by pumice stone. Essentially, thermocol balls are used in place of pumice stones while washing knitted clothing, combined with a range of chemical concentrations to create various fading effects. Additionally, any chemical cleaning of knit clothing causes the colors to fade, giving the garment a contrast effect [17-18]. An investigation on the effect of acid wash was conducted on the physical properties of a single jersey 100% cotton T-shirt, a single jersey 95% cotton 5% spandex T-shirt, and a rib 100% cotton T-shirt. The study reported that fabric weight per unit area, stitch density, spirality, and shrinkage increased while bursting strength and stitch length absorbency decreased after acid washing treatment, along with a little decrease in colorfastness to wash, wet, and dry rubbing but there was no change in pilling [19]. The present study aims to apply acid washing to Terry and interlock knitted garments using potassium permanganate and thermocol balls in order to investigate the physical and mechanical properties of these garments in terms of weight per unit length, spirality, bursting strength, wash fastness, and dry-to-wet rubbing fastness.

2. Materials and Methods

2.1 Raw materials

Two knitted garments were used in this study, namely 100% cotton with terry construction and 100% cotton with an interlock structure. Both garments were dyed with reactive dye at their fabrication process. The grams per square meter of Terry and Interlock garments were 260 and 270, respectively.

2.2 Acid washing process

A solution was prepared using washing agents of potassium permanganate and phosphoric acid. 5% phosphoric acid and 15 g/L potassium permanganate were used. Thermocol balls were loaded into the washing machine on the basis of 0.1% of garment weight. Washing solution was added into the machine. Washing was carried out with the garment for 10 minutes. Material and liquor ration was kept at 10:1. Washing liquor was drained for neutralization according to the process parameters at room temperature. The garment was brought out from the machine; dewatering was done by hydroextraction, and the garment was dried at the end. The process flow of the acid washing is shown in the process flow diagram, and the process parameters are mentioned in Table 1.

Table 1. Process parameters of acid washing.

|

Process |

Parameters |

Amount |

|

Acid Washing |

Potassium permanganate |

60 g/L |

|

Phosphoric acid |

10 g/L |

|

|

Temperature |

Room |

|

|

Time |

10 min |

|

|

Neutralization |

Sodium metabisulphite |

2 g/L |

|

Temperature |

Room |

|

|

Time |

10 min |

2.3 Flow chart for the acid washing process

2.4. Assessment of physical properties

Fabric grams per square meter (GSM) was measured according to the ASTM D 3776 method by GSM cutter. Dry and wet rubbing color fastness were tested according to AATCC 8 by Crockmeter. Color fastness to wash was measured according to ISO 105 C06 Method. Spirality was measured according to AATCC Test Method 187-2013. Pilling tests of the garments were tested by the ICI Pilling box according to the ISO 12945-1:2001 method. The ISO 13938-2:2019 method was used to test the bursting strength of garments.

3. Results and Discussion

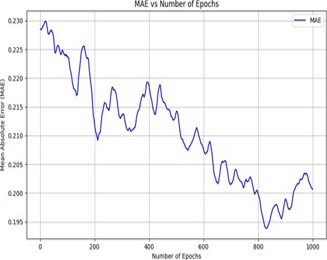

3.1 Garments appearance

After acid washing on reactive dyed knitted garments, there was a huge change in the appearance of the garments, and the color was lighter than before washing. Fig. 1 portrays the fading and color change scenario of the garments.

Fig. 1. Color change of garments before and after acid wash.

Acid washing acid and thermocol balls with solution breaks the chemical bond of the primary wall of the cellulosic fibers of the garments, and after that, it slightly attacks the secondary wall. Therefore, weakly bonded dye particles are removed from the fabric surfaces, and fabric color fading occurs as a burnt look.

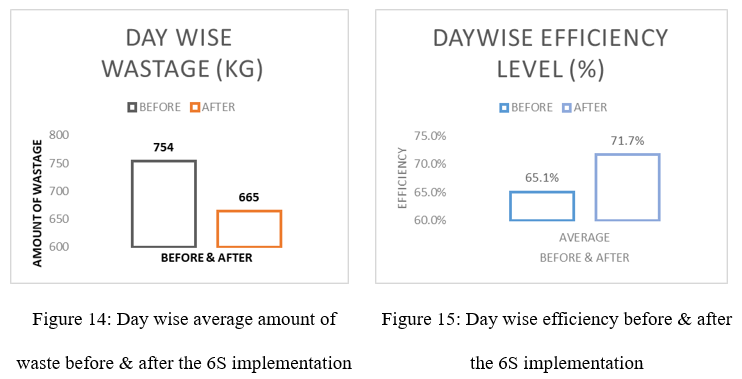

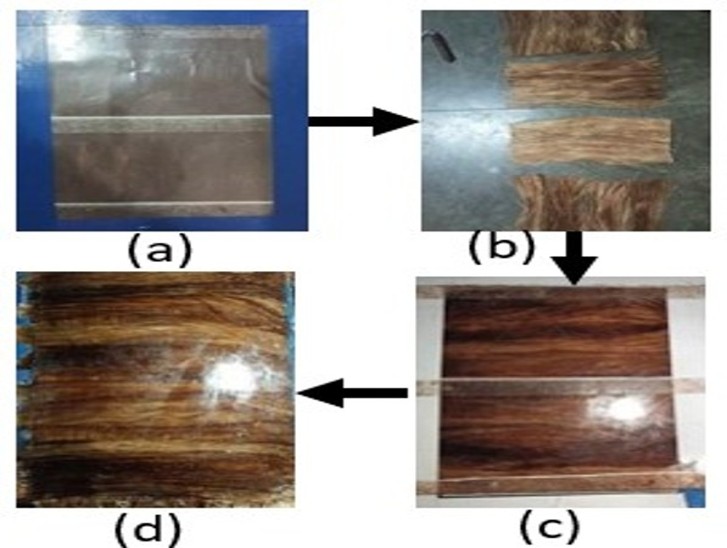

3.2 Effect on grams per square meter (GSM)

The GSM of the sample (Terry and interlock) before and after acid washing changed as displayed in Fig. 2.

Fig. 2. GSM change of garment before and after acid wash.

It can be observed that the weight of the fabric per unit area (GSM) increased after washing. When the knitted garments are faced with frictional action due to the thermocol balls and rotating cylinder of the washing machine, a trace of solution of potassium permanganate (KMnO₄) and phosphoric acid (H3PO4) also penetrates the fiber structure, causing the change in internal tension in the constituted fibers of the garments. The garments then tended to revert to their dimensions, which resulted in the contraction of the yarns. This effect causes the reduction of the stitch length, and thereby the GSM of the fabrics is increased.

3.3 Effect on bursting strength

It is found that the acid washing treatment on knitted garments causes a decrease in bursting strength as portrayed in Fig. 3.

Fig. 3. Change in bristling strength of garments before and after acid wash.

At first, thermocol balls with solution break the chemical bond of the primary wall of the cellulosic cotton fibers, and after that, they slightly attack the secondary wall. The result of this reaction is that the primary wall of the cotton fiber is loosened and broken down quicker with the mechanical forces of the washing machine and the slightly rough surface of thermocol balls. As a result, the internal hydrogen bonding force among the molecules of the cellulose gets reduced, which causes lower strength. This causes a loss of bursting strength after acid washing.

3.4 Effect on color fastness, pilling, and pH

It is evaluated that the value of colorfastness and pilling was unchanged before and after acid wash for both garments tabulated in Table 2 for multifiber fabric staining.

Table 2. Effect of physical properties of garment before and after acid wash.

|

Properties |

Before acid wash (Terry and Interlock) |

After acid wash (Terry and Interlock |

|

Color Fastness to Wash |

4-5 |

4-5 |

|

Color Fastness to Dry Rubbing |

4-5 |

4-5 |

|

Color Fastness to Wet Rubbing |

2-3 |

2-3 |

|

Pilling |

4-5 |

4-5 |

|

pH |

6.81 |

6.83 |

As acid damages the primary wall of the fibers of the garment and also removes weakly bonded dye particles on fiber surfaces, it therefore shows very good rubbing fastness. As weakly fixed dye particles are removed during acid washing, the garment shows good wet rubbing properties like before washing. From the result, Table 2 shows that the value of color fastness to wet rubbing is unchanged. Reactive dyeing is done in an alkaline medium where the pH ranges from 9 to 10. After dyeing and normal washing, neutralization was done. Then acid washing was done in an acidic medium where the pH range is 4.5-5.5, then neutralization was done. Reactive dye creates a strong bond with hydroxyl groups of cellulosic cotton fibers. Also, weakly fixed dyes are removed during acid wash and fabric fade, and the garment shows good color fastness to washing and rubbing. pH remains almost unchanged after performing these tests. The slight variation that happens between before and after acid wash can be the result of the variation in neutralization. The reason for having no change in pH in the before- and after-acid wash garment is the neutralization (by sodium metabisulphite and acetic acid) process. The garments were subjected to neutralization at the end of each process. If neutralization had not been done, the acid-washed garment would have shown a lower pH because acid wash was performed with a pH of approximately 4-5, whereas the pH of the garment after the dyeing and neutralization process was 6.5. There were no changes found in pilling after acid wash even with the abrasive nature of thermocol balls.

3.5 Effect on spirality

The effect on the spirality of the washed garments is shown in Fig. 4.

Fig. 4. Changes in the spirality of the garment before and after acid washing.

From Fig. 4, it’s observed that spirality after washing increased. During washing, dimensional stability slightly decreases due to the reaction of acids with the primary wall of cellulosic fibers. The amount of spirality increases after acid wash. Interlock fabric, having a compact structure, shows the least spirality. On the other hand, terry fabric, having a loose structure, shows higher spirality.

4. Conclusion

The experiment aimed to find out the effect of acid wash on reactive dyed knit garments. Two types of coarse garments (Terry 100% cotton and interlock 100% cotton) were selected, and acid washing with thermocol balls was conducted. It was noticed that acid washing faded the color of the garment and created a burnt-out shade for dyed garments. The GSM and spirality of the garment increased after acid wash for terry and interlock garments. On the other hand, bursting strength decreased after acid washing. Additionally, other properties like pilling and colorfastness to washing, drying, and wet rubbing remained unchanged after acid washing for both garments. This study suggests that acid wash can add value to the knit garment for creating a fashionable appearance.

REFERENCES

[1] Sanders Deaja, Grunden Amy, Dunn Robert R. “A review of clothing microbiology: the history of clothing and the role of microbes in textiles” Biol. Lett.2021.

[2] Sonkar P. A., Muthusamy A. “Impact of Fashion Trends on Visual Merchandising for Promoting Fashion Apparel Brands”, Journal of Service Science and Management, Vol.16 No.4, August 2023.

[3] Abir Ben Fraj, Boubaker J. “Effects of ozone treatment on denim garment properties”, Coloration Technology, Vol. 37, Issue 6, December 2021, 678-688.

[4] Israt Zerin Ansari, “Impact of Stone Wash and Acid Wash on the Physical Properties of Denim”, International Journal of Engineering Research, Vol. 6, Issue No.12, 499- 501.

[5] Suman Mazumder, “Daffodil International University Journal of Science and Technology, “Effect of Sand Balsting with Industrial Enzyme Silicon Wash on Denim Apparel, Vol. 5, Issue 1, 2010.

[6] Ji Ming Yao, Sai Nan Wei, “Effects of Potassium Permanganate Decoloration on Denim Shade”, Advanced Materials Research, Vol. 627, 190-194.

[7] Mafzal A. Md Piash A. Moynul H. “An explanation of bleach wash on denim cotton fabrics”, J Textile Eng Fashion Technol. 2021;7(3):87‒90.

[8] Thanabal V, Gopalakrishnan M, Vijayasekar RThanabal V, Gopalakrishnan M, Vijayasekar R, Study on the the Quality Characteristics of Slub Yarn Knitted Fabrics, Journal of Fibre and Textile Engineering, Vol.1 Issue 1, May 2021, 10-14.

[9] Anwar H., Shamimul H., M. Mohiuddin, M. Reajul Islam, “A novel approach to produce neppy yarn in vortex spinning technology” The Journal of The Textile Institute.

[10] Farhana Afroz, MD. Momtaz Islam, “Study on Mechanical Property of Woven Fabrics Made from 50/50 Cotton-Tencel Blended Siro Yarn”, Heliyon, Vol.7, Issue 10, 2021.

[11] Mukhopadhyay, A., Midha, V. K., & Ray, N. C, “Effect of structural parameters of injected slub yarn on its tensile properties and abrasion resistance”, The Journal of The Textile Institute, 108(9), 1496–1503.

[12] Md. Shohan Parvez, Md. Ishtiaque Rahman, Tarikul Islam, S.M. Razwan Ahmed, Quality Optimization by Evaluating Physico-Mechanical Properties of Industrial Acid Wash, Cool Dyeing and Dip Dyeing Processes on Knitted Garment, International Journal of Engineering and Advanced Technology, Vol. 9 Issue-1, 2019.

[13] Khalil, E., Rahman, A. & Solaiman, M. (2015) Investigation on Simultaneous Effect of KMnO4 Concentration and Processing Time on Tensile Strength, Weight and Stiffness of Denim Jeans During Acid Washing with Pumice Stone. International Journal of Research & Review, 2, 546-550.

[14] Khalil, E. (2015) Investigation of the Influence of Potassium Permanganate on Denim Jeans Processing during Acid Wash. AASCIT Communication, 2, 271-275.

[15] Khalil, E. (2015) Effect of Processing Time and Concentration of Potassium Permanganate on Physico- Mechanical Properties of Denim Jeans during Stone Washing. Science Innovation, 3, 68-71.

[16] Agham Rahul, D. (2012) State-of-the-Art Insulation Materials: A Review. International Journal of Engineering and Innovative Technology, 2, 97-102.

[17] What Is Thermocol? And What Is Its Manufacturing Process? Retrieved on 31 January 2016.

[18] Elias Khalil, Masud Rana, Jewel Faria, Al-Amin Islam, Sohel Rana, Investigation on Effect of Acid Wash with Thermocol Ball on Physical Properties of Knitted Garments, Journal of Textile Science and Technology, 2016, 2, 16-21.

Georgia Reader Reply

Et rerum totam nisi. Molestiae vel quam dolorum vel voluptatem et et. Est ad aut sapiente quis molestiae est qui cum soluta. Vero aut rerum vel. Rerum quos laboriosam placeat ex qui. Sint qui facilis et.