Reduction of Non-Productive Time in Apparel Manufacturing: A Garment Factory Case

Abstract

Rimsa Taimy1* and Shafiullah Khan2

1Department of Apparel Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh

2Department of Textile Engineering Management, Bangladesh University of Textiles, Dhaka, Bangladesh

1Contact: rimsataimy@gmail.com

Received: March 10, 2025; Revised: March 28, 2025; Published online : March 30, 2025

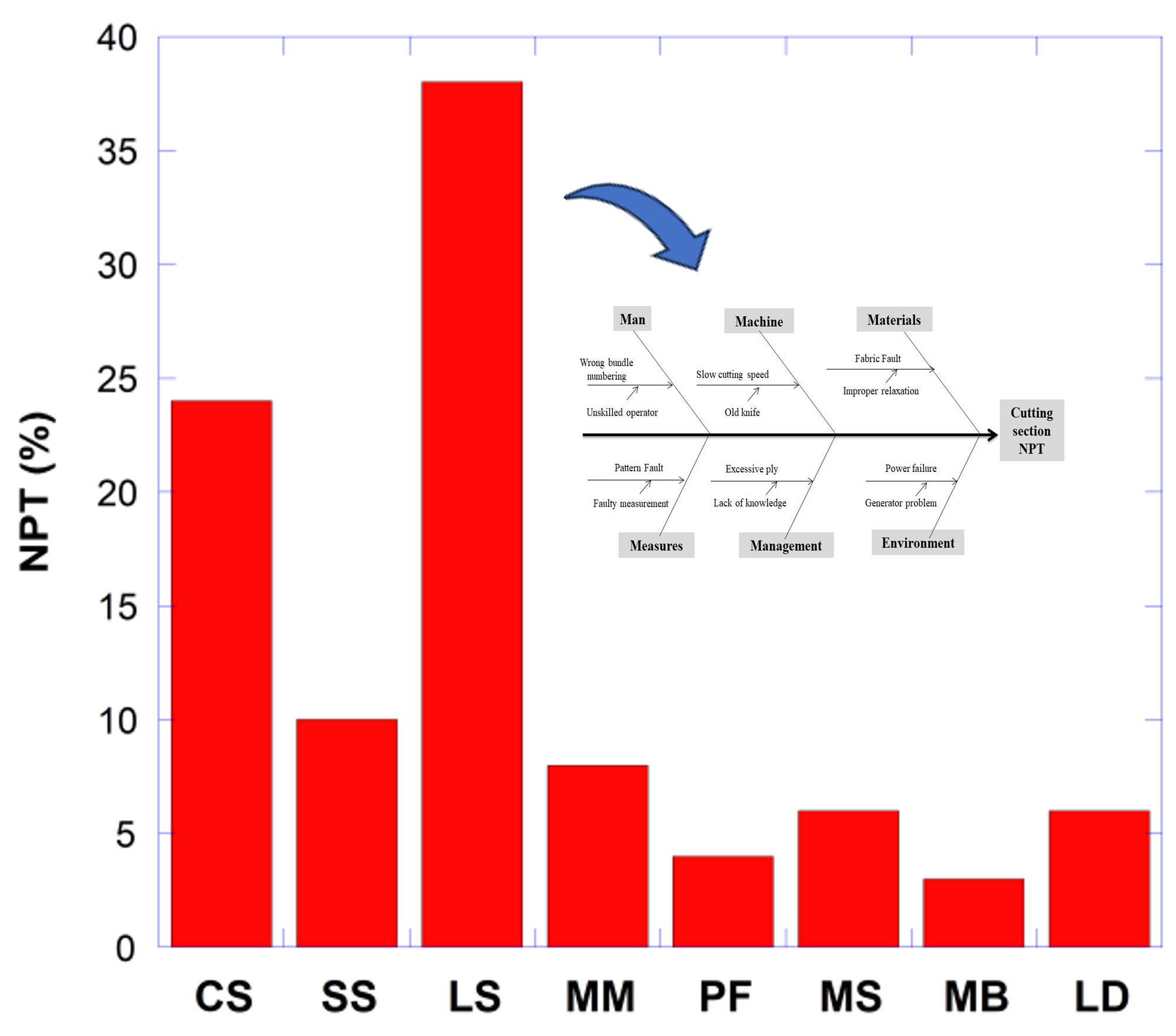

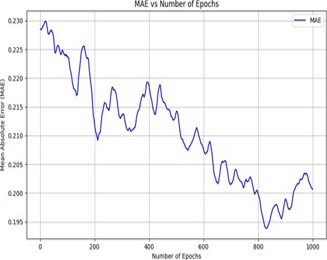

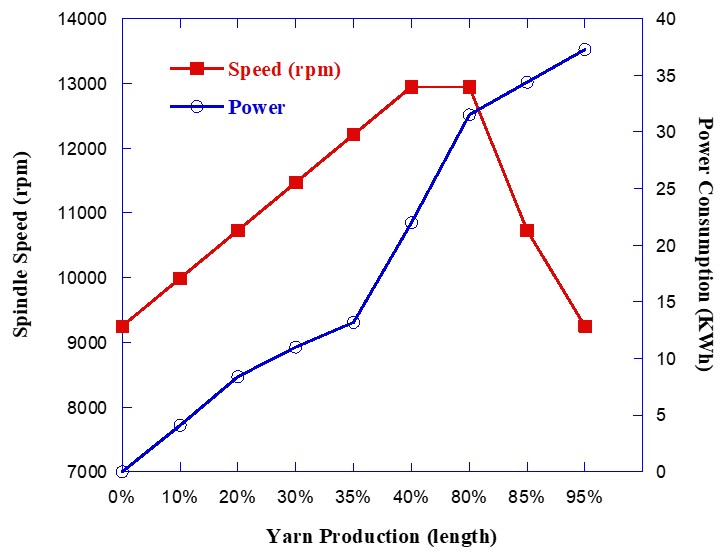

Garment manufacturers constantly seek methods to improve efficiency and productivity. Thus, the study was undertaken to identify non-productive time (NPT) and analyze the root causes. The effect of NPT on productivity standard minute value, labor efficiency, and targets was also analyzed in an apparel manufacturing unit of Bangladesh. The study discusses various approaches to reduce NPT. These include applying time study why-why-bacause of logic (WWBLA), fishbone techniques to minimize the NPT of cutting and sewing process, and detecting the reason for NPT through root cause analysis and the process through which it can be reduced. The effectiveness of these strategies demonstrates efficiency gains and positive impacts on productivity. The productivity improved 6-10% after taking countermeasures against the NPT. The study highlights the importance of precise time measurements and workflow analysis in identifying and eliminating NPT. By implementing these methods, garment manufacturers can achieve operational excellence, minimize process waste, and enhance competitiveness.

Georgia Reader Reply

Et rerum totam nisi. Molestiae vel quam dolorum vel voluptatem et et. Est ad aut sapiente quis molestiae est qui cum soluta. Vero aut rerum vel. Rerum quos laboriosam placeat ex qui. Sint qui facilis et.