Repetitive Upcycling of Waste Flax Fibre: A Circular Economy and Sustainability Approach in Yarn Manufacturing

Abstract

Khen Maung1, Mohammad Ali2, Md. Musa Miah3

1 NZ Tex Group (Textile Ltd. & NZ Apparels Ltd.), Narayangonj, Bangladesh

2 Department of Industrial and Production Engineering, Bangladesh University of Textiles (BUTEX), Dhaka, Bangladesh

3 Department of Quality Control & Assurance, NZ Textile Ltd., Narayangonj, Bangladesh

Corresponding Author: maung.nzgroup@gmail.com

Received: February 22, 2025; Revised: March 20, 2025; Published: April 15, 2025

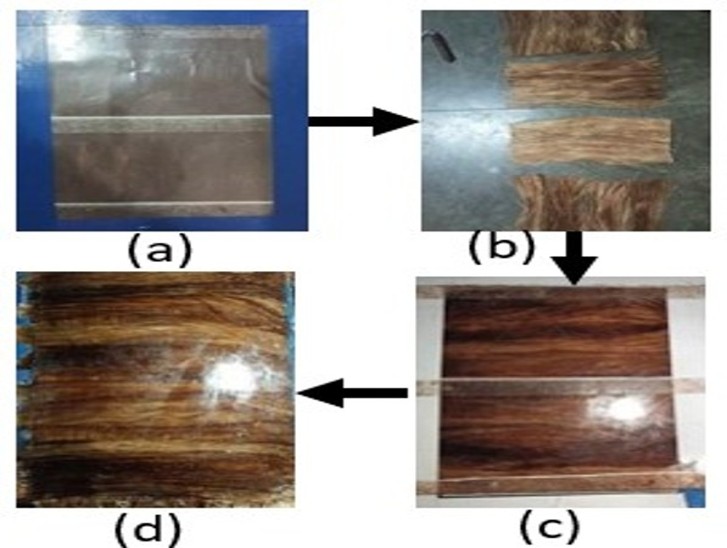

The implementation of sustainable waste management techniques is required due to the growing environmental concerns facing the worldwide textile sector. Waste from the production process of linen yarn, which is frequently wasted or underutilized, presents a promising opportunity to produce sustainable flax fibre blended yarn with additional value by upcycling. This study explores the upcycling of waste flax from the linen yarn manufacturing process (wet spinning) in order to manufacture blended yarns. Waste flax from the wet spinning process was cottonized by a mechanical system. The cottonized waste flax fibre was used to produce four types of primary blended yarns of similar count (21 Ne) and blend ratio of 45:55 (45% virgin cotton/viscose/polyester/tencel, 55% cottonized waste flax fibre) in a ring spinning process. The primary blended yarns of cotton-flax (CFp), viscose-flax (VFp), tencel-flax (TFp), and polyester-flax (PFp) showed good evenness and tensile properties. Again, waste (flat strip of cotton-flax) from the carding process during the production of CFp yarn was cleaned and reused by adding virgin cotton to produce a secondary blended cotton-flax yarn (CFs) of 20 Ne at a ratio of 70:30 (cotton: flax) in a ring spinning process. The CFs also showed acceptable evenness and tensile properties compared to CFp yarn. The cost analysis suggested that both primary and secondary blended yarns of process waste flax were less than the blended yarn produced from virgin cottonized flax fibre. The study successfully revealed a process waste management technique to develop a circular economy with industrial-scale economic benefits by turning low-value fibre waste into valuable yarns.

Georgia Reader Reply

Et rerum totam nisi. Molestiae vel quam dolorum vel voluptatem et et. Est ad aut sapiente quis molestiae est qui cum soluta. Vero aut rerum vel. Rerum quos laboriosam placeat ex qui. Sint qui facilis et.