The Influence of Humidity Control on Jute Yarn Quality: A Path Toward Sustainability

Abstract

Md Mehedi Hasan Niloya*, Shoaib Islam Zicob, Rafid Ahmed Chowdhurya, Mahmudul Hasan Pervesc, Elias Khalild

aDepartment of Industrial and Production Engineering, Shahjalal University of Science and Technology, Sylhet-3114, Bangladesh

bDepartment of Jute and Fibre Technology, University of Calcutta, Kolkata, West Bengal 700073, India

cDepartment of Industrial and Production Engineering, Shahjalal University of Science and Technology, Sylhet-3114, Bangladesh

dTangail Textile Engineering College, Tangail, Bangladesh.

Corresponding Author: mehediniloy334010@gmail.com

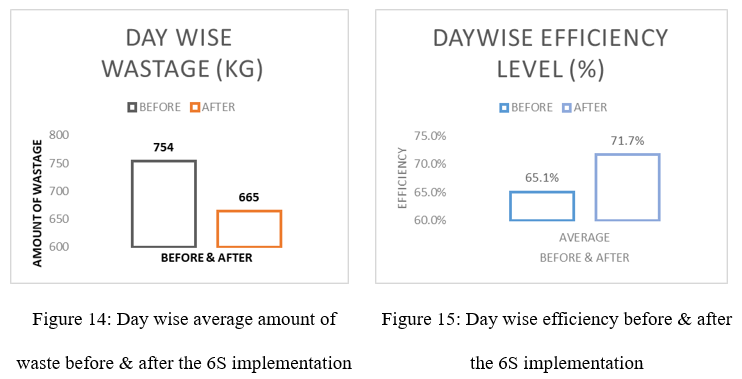

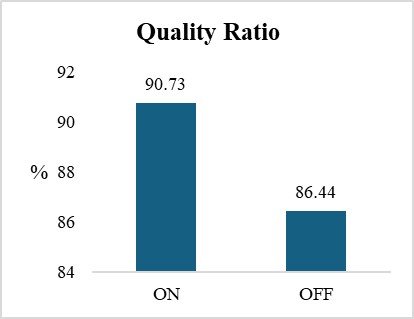

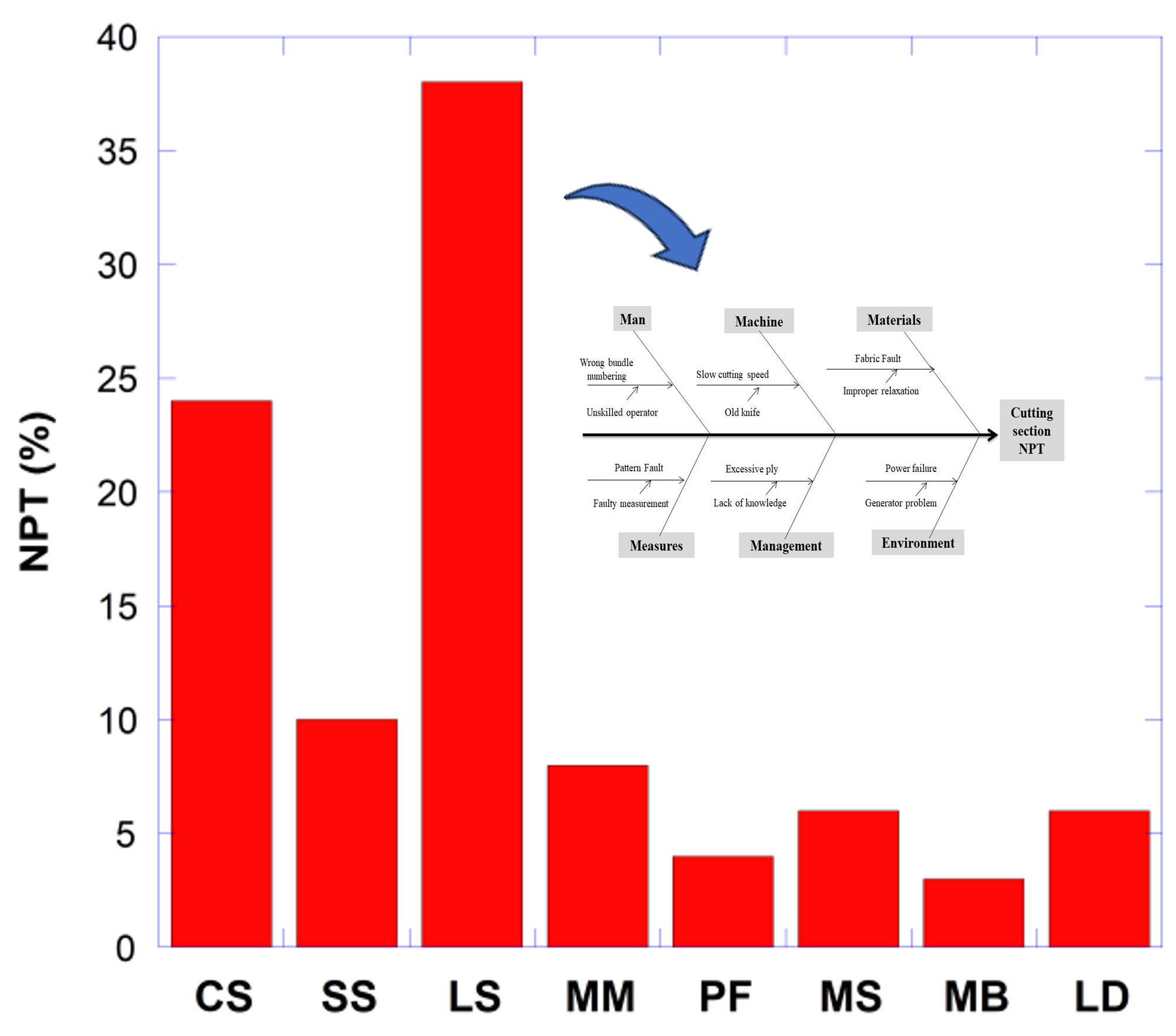

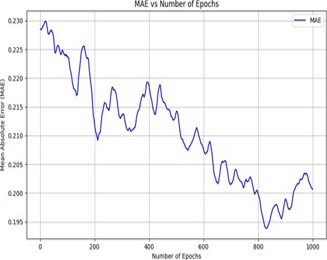

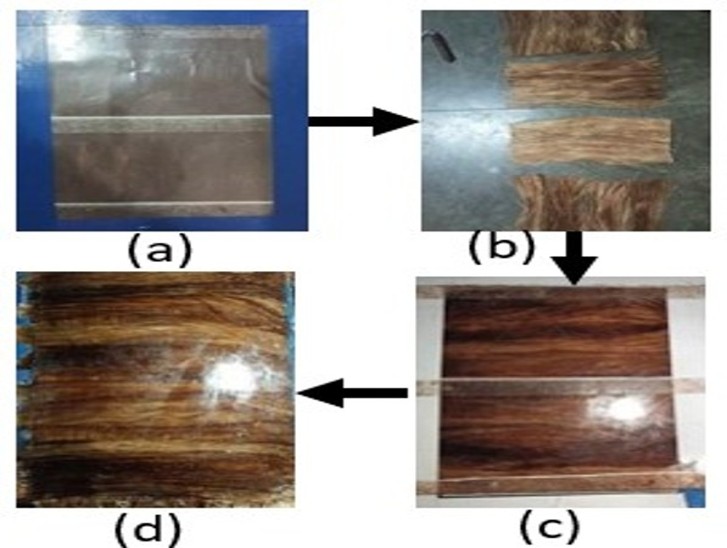

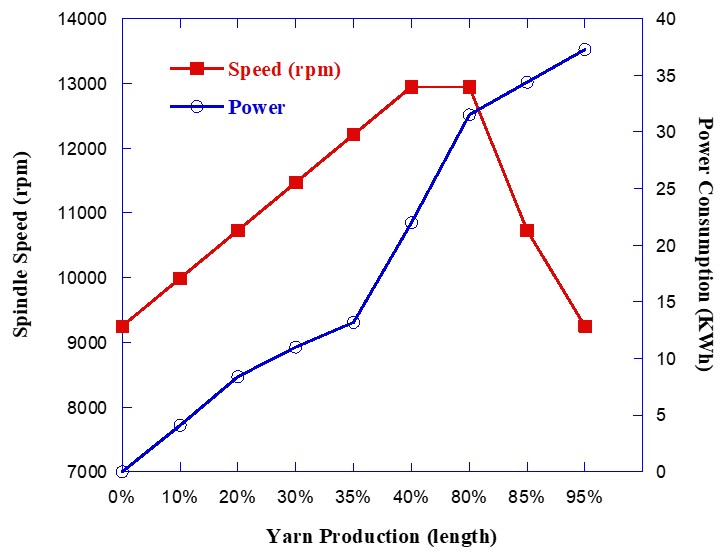

Jute, a natural hygroscopic fiber, is highly sensitive to environmental humidity, which significantly affects its physical properties. This study examines the impact of a humidity control system on jute yarn quality during spinning, focusing on yarn count, breaking strength, moisture content, quality ratio and twists per inch (TPI). Experiments were conducted under two humidity conditions: 67% relative humidity (RH) (system active) and 52% RH (system inactive). Results indicate that maintaining optimal humidity (67% RH) enhances yarn quality by improving tensile strength (+9.7%), reducing end breakages (-78.6%), and ensuring consistent yarn count and TPI. Higher humidity reduces fiber brittleness, leading to better fiber integrity and reduced production inefficiencies. In contrast, lower humidity resulted in inconsistent yarn properties and increased breakages. These findings emphasize the importance of humidity control systems in enhancing jute yarn quality, reducing waste, and improving efficiency in textile manufacturing.

Georgia Reader Reply

Et rerum totam nisi. Molestiae vel quam dolorum vel voluptatem et et. Est ad aut sapiente quis molestiae est qui cum soluta. Vero aut rerum vel. Rerum quos laboriosam placeat ex qui. Sint qui facilis et.